To produce epoxy polymers, epoxy resins are mixed with a hardener, producing an inert thermoset material.

The finished, hardened epoxy does not pose any health risk and offers superior performance, including excellent adhesion, mechanical properties, corrosion, and chemical resistance.

Epoxies are widely used in numerous applications. They need to be handled in a professional manner following established safety procedures. The components of epoxy systems may have hazardous properties and can become dangerous in contact with human skin. However, they are perfectly safe to handle, provided that basic precautions are taken.

Epoxy Europe has developed a series of documents to assist and inform epoxy users. These guidelines describe situations with a risk of contact with an epoxy system and offer straightforward advice for safely handling these products.

Did you know?

This information is especially designed to support craftsmen, business managers, safety and education managers in selecting and providing suitable organisational, technical and personal safety tools and procedures. But they cannot replace the specific safety instructions given for each product, which must always be respected in its entirety. The common goal is to prevent incidents or health problems and support the continued safe use of epoxy systems in all applications.

Watch our animation to learn how to

handle epoxy resins safely!

EPOXIES IN THE WORKPLACE

Some Safe Handling Initiatives in the EU

Epoxy resins are specially designed performance materials that must be handled with the necessary care, like every product used in high-performance applications. As much as a scalpel is indispensable for a successful surgery, handling it sensibly from the first use is highly important. User education and training right from the very start is thus key to the successful and safe handling of epoxy resins. Therefore, providing comprehensive information during training is desirable for jobs that may have to handle epoxy resins. This way, it is ensured that the applicant is aware of the correct handling procedures for epoxy resins and does stringently adhere to the necessary protection measures.

Sensitisation

Epoxies are not difficult to use. However, they still require some attention in the workplace. Repeated unprotected contact with skin can trigger a body reaction called “sensitisation”, which shows similar symptoms as an allergic reaction.

Sensitisation can only occur with uncured resins since cured systems are harmless due to the absence of reactive epoxy groups. To avoid this, wearing protective equipment at all times when working with reactive epoxy resins is crucial. Proper workplace hygiene is the best measure to prevent allergies[1].

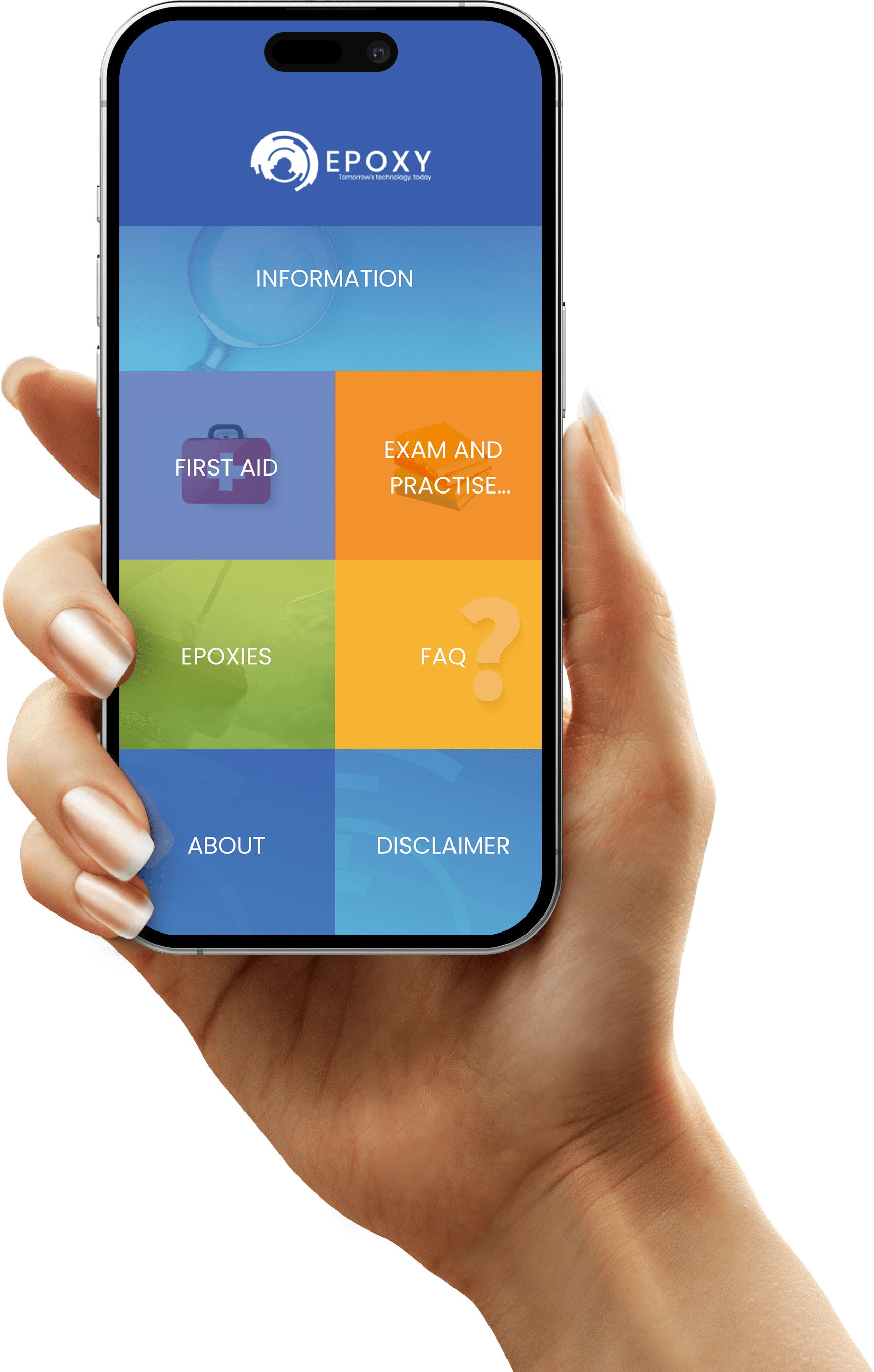

The Epoxy Europe

Safety App

The Epoxy Europe Safety App is an online tutorial designed to provide expert information to epoxy users for working with epoxy resins safely.

Learn More

DENMARK

Denmark has mandatory training schemes for people working with epoxy resins since 1981. An analysis of patch test data from the Danish Contact Dermatitis Group[1] showed that, despite such preventive measures, problems concerning sensitisation to epoxy remain. Efforts to ensure that all protective equipment is worn should continue.

[1] https://www.researchgate.net/publication/224887234_Occupational_contact_dermatitis_in_painters

* DGUV: Deutsche Gesetzliche UnfallVersicherung

GERMANY

The German Mandatory Workers Insurance (DGUV*) and the University of Osnabrück developed training materials to support teachers, especially at professional schools, in this task. The INQA (Initiative Neue Qualität der Arbeit) Project has been active since 2007. The goal is to reduce the number of cases of sensitisation in the workplace related to handling epoxy resins.

Other initiatives include successful and productive cooperation between all stakeholders (Insurance providers, German Social Accident Insurance Institutions (BG), industry, IVDK) and collaboration with neighbouring countries like Austria, Switzerland or the Netherlands.

They can be found under following links (German only):

https://www.dguv-lug.de/berufsbildende-schulen/gesundheitsschutz/epoxidharze/

https://www.dguv-lug.de/berufsbildende-schulen/gesundheitsschutz/epoxsafe/

Similarly, the project EpoxSafe@School by the University of Osnabrück and the German Institute for Health Research and Education (ITUC) – Department of Dermatology, Environmental Medicine and Health Theory develop training to prevent sensitisation. Training start with apprentices at school and move on to the teachers.